Having issues recovering all of your property’s water consumption even though you have submeters? You are not alone, as this is a common problem we run into for a variety of reasons. Many people make the assumption that your master meter consumption should equal the aggregate of submetered consumption on a given site, given that every point using water is submetered.

On the surface this seems like a fair assumption. In this article we’ll discuss some of the reasons this could be far from the truth, as well as new metering technology aimed at rectifying such situations. We’ll cover the following reasons your submeters may not be measuring consumption accurately and some solutions for these problems:

- Incorrectly Sized Meters

- Incorrectly Installed Meters

- Aging Meters

Incorrectly Sized Meters

To demonstrate how incorrectly sized meters can affect your consumption measurement, we'll use commercial applications as an example. One of the inherent challenges with commercial metering is that tenants and build-outs change over time, and many times aren’t even known during initial construction. The solution is typically to overestimate the amount of water needed to be on the safe side. After all, the last thing anyone wants is to have a tenant experience insufficient water supply or pressure loss due to an undersized water meter.

Let’s say the space was intended for fairly high water consumption and a 2” turbine water meter was installed to handle 4-350 gpm, which covers a wide range of water demand. This means that in order to meet AWWA standards for accuracy, the meter needs to be 98.5-101.5% accuracy at 4 GPM. A typical turbine meter might fall to 95-105% accurate at very low flow of 3 gpm, and below 3 gpm, the accuracy can drop significantly and given a low enough flow very little consumption could be picked up.

Now let’s say the space ends up being a low volume of water consumer, such as a department store with bathrooms, water fountains, break room and things of this nature. On the surface, one might assume all water consumption would be accounted for because the meter is overkill for the size of space. However, it can be just the opposite: Because the 2” turbine meter was designed for higher flows of water, the result can be a very low recovery. This is because many features such as drinking fountains, sinks, showers and toilets can use less than 3 gpm, which is below the designed low flow of the meter which could result in significant under recovery of water consumption. In addition, a traditional turbine meter with a low flow of 3 gpm could potentially not register slow leaks, which can add up over time.

One way this issue was addressed in the past was a solution called the Compound Meter. This meter functions basically as two meters, with a crossover between the larger meter during high flow times and the smaller meter during low flow times. However, even this solution can result in cross-over losses up to 15%, which historically was deemed acceptable.

Incorrectly Installed Meters

This is a fairly common issue we see, as most people are not aware of the installation limitations of various meter types. Let’s take the same 2” turbine water meter in the example above. If this meter is installed upside down for example (which seems logical to many people because if the meter is overhead, installing the meter with the register facing down would make sense in order to be able to read the meter), you could be in for major accuracy issues, not to mention unnecessary wear and tear on the meter which shortens the meter’s life. This is because the meter has mechanical parts internally which are designed to operate with the meter register facing up.

Another common problem is a missing strainer prior to the meter. Most large turbine meters do not include an internal strainer like smaller multijet meters. If the installer does not install a meter strainer prior to the meter, debris can accumulate in the meter over time and cause additional wear and tear, void the warranty and result in inaccuracy or complete meter failure prematurely.

When not installed correctly, inaccuracy and additional wear can go unnoticed for years, because the meter appears to be “functioning”, as some accumulation of water consumption will continue to occur. The results are low revenue recovery and high maintenance costs over time.

Aging Meters

As alluded to in the previous section, another issue with traditional mechanical meters is that internal components can wear out over time, resulting in a loss in accuracy. The amount of accuracy loss can depend on many factors such as meter quality, water quality, quality of installation, volume of water and the age of the meter to name a few. Once again, the problem can go unnoticed because the meter appears to be functioning and accumulating water consumption.

Meters which have been installed 10-15+ years are at especially high risk of inaccuracy due to aging and should be tested for accuracy.

Solutions to Water Recovery Issues

It is not uncommon to see recovery issues from 10-40% depending on the severity of the situation, which can mean significant revenue losses if not addressed. The good news is that products and technology improve over time in every industry, with water metering being no exception.

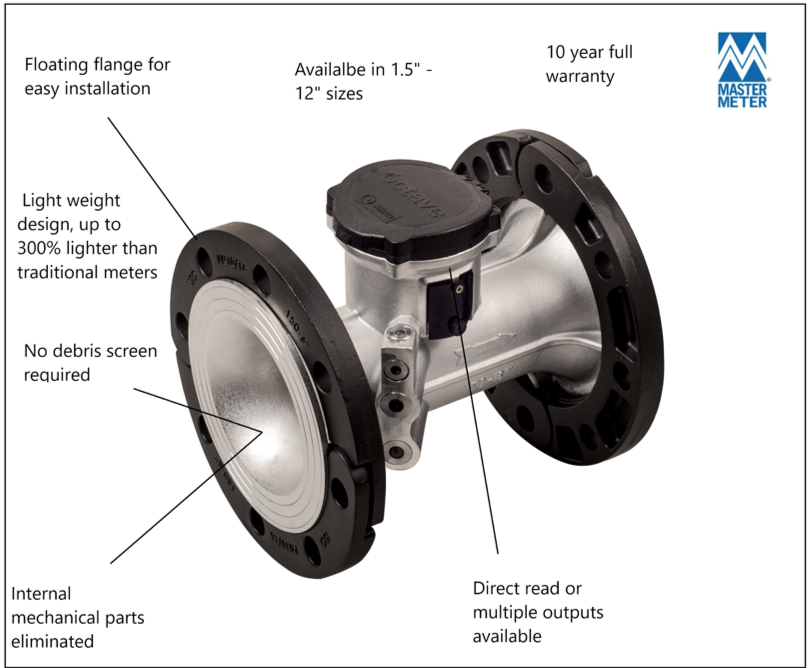

One great example is the adoption of ultrasonic technology, such as the Octave Ultrasonic Meter product line from Master Meter. With ultrasonic meters, mechanical parts are eliminated, creating a solid-state meter which can be installed upside down, vertical or horizontal, without the need for a strainer, and reach low flows as low as 1/16 gpm.

If your goal is to install a meter with flexible line size adaptability, meaning, the meter will maintain accuracy for high and low flows, the Octave product line from Master Meter is ideal. For example, the 1.5” Octave water meter allows for a wide range from .5 GPM low flow to up to 250 GPM high flow, while maintaining AWWA accuracy. This improved technology allows for more flexibility at installation and longer term accuracy, even as variables change down the road.

Conclusion

In the end, there is no exact formula to calculate when accuracy issues will arise and to what extent, as different projects have different variables. This is why it is best to monitor your recovery and have a proactive meter maintenance and replacement program in place to ensure maximum recovery for the long-term.

Whether the project is large or small, multifamily or commercial or anything in between, there are solutions to help you maximize recovery. If you’d like more information on metering technology or would like to discuss solutions for your project, please fill out our contact form and we’ll reach out and set up a time that works for you.

If you already know the meter you need, our online store is available with a variety of meters to fit a wide range of applications and products typically ship within 1 business day.